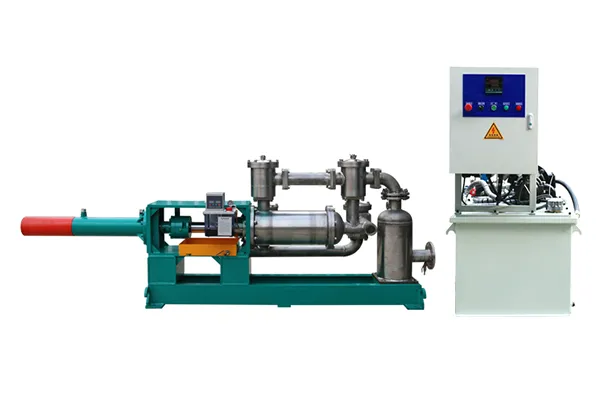

Horizontal Plunger Pump for Screw Pump Replacement

Energy-saving filter press feed pump for replacing screw pump in slurry handling applications

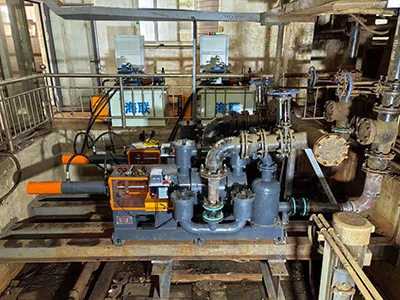

To meet customer needs for replacing screw pumps in filter press systems, we developed a custom horizontal plunger pump specifically designed for the narrow and elongated installation spaces typical of screw pump layouts. Based on on-site operational feedback, the redesigned horizontal plunger pump ensures adequate maintenance clearance, stable operation, low noise, and zero vibration, earning consistent positive feedback from clients.

Technical Parameters

| Model | Rated Flow (m³/h) | Feed Pressure (MPa) | Head (m) | Motor (kW) | Cooling Method | Inlet/Outlet Flange | Cylinder Material |

|

|

3 | 1.5 | 150 | 3 | Air cooling | DN50 | 45#/304/316L/2205 (Available options) |

|

|

10 | 1.5 | 150 | 3 | Air cooling | DN80 | |

|

|

15 | 1.5 | 150 | 4 | Air cooling | DN80 | |

|

|

20 | 1.5 | 150 | 5.5 | Air cooling | DN80 | |

|

|

35 | 1.5 | 150 | 5.5 | Air cooling | DN80 | |

|

|

48 | 1.5 | 150 | 7.5 | Air cooling | DN100 | |

|

|

60 | 1.5 | 150 | 9 | Air cooling | DN100 | |

|

|

80 | 1.5 | 150 | 11 | Air cooling | DN100 | |

|

|

100 | 1.5 | 150 | 15 | Air cooling | DN100 | |

|

|

120 | 1.5 | 150 | 18.5 | Air cooling | DN100 | |

|

|

140 | 1.5 | 150 | 18.5 | Air cooling | DN125 | |

|

|

160 | 1.5 | 150 | 22 | Air cooling | DN125 | |

|

|

200 | 1.5 | 150 | 37 | Air cooling | DN125 | |

|

|

250 | 1.5 | 150 | 45 | Air cooling | DN150 | |

|

|

300 | 1.5 | 150 | 55 | Air cooling | DN150 |

Features

- Energy saving: Compared with traditional slurry and screw pumps, the horizontal plunger pump reduces motor power consumption by 50%–80%, significantly lowering operational costs.

- Higher pressure and efficiency: The pump delivers output pressure up to 2 MPa, greatly improving filtration efficiency, increasing filter cake thickness, and reducing moisture content.

- Upgraded sealing and guiding structure: A universal joint absorbs misalignment between the hydraulic cylinder, coupling, material cylinder, and mounting frame, effectively reducing seal-ring wear.

- Custom sealing materials: Built with specialized sealing materials and structures to greatly extend seal life.

- Smart lubrication system: Timed and metered lubrication is applied between guide seals through a closed-loop lubrication system, preventing oil waste and environmental contamination. Controlled lubrication also avoids accelerated seal wear caused by human error.

- Longer service life: Low-speed reciprocating (back-and-forth) motion extends the lifespan of core components compared with high-speed reciprocating pumps.

- LED status indicators: Visual LED lighting indicators allow operators to quickly identify pump status by color. Commands are issued, processed, and monitored through the integrated PLC system.

- Optimized for narrow installation spaces: The pump is specially customized for elongated and tight spaces typical of screw pump applications while ensuring sufficient maintenance access, stable operation, low noise, and vibration-free performance.

On-Site Application