Hydraulic Pile Breaker

Pile breaking tool for safe and quick cutting of concrete pile heads

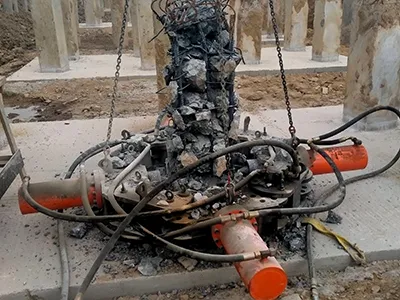

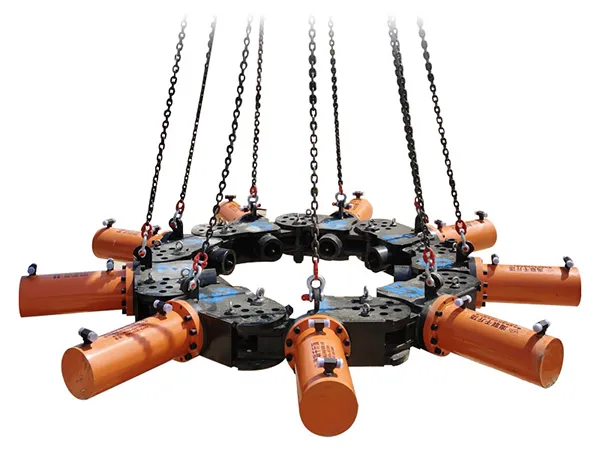

The hydraulic pile breaker is widely used in foundation engineering as an efficient, environmentally friendly machine for quickly and safely removing excess concrete pile heads after excavation. It is also suitable for small-scale foundation demolition, concrete pavement removal, and bridge pier demolition. The hydraulic pile breaker replaces traditional methods such as pneumatic picks and manual hammering, making it the preferred equipment in modern construction.

Technical Parameters

| Model |

|

|

|

|

|

|

|

|

|

| Pile Diameter (mm) | 400-600 | 600-700 | 800-900 | 900-1100 | 1100-1300 | 1400-1600 | 1700-2000 | 2100-2200 | 2300-2500 |

| Modules | 4 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 |

| Stroke (mm) | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Working Pressure (MPa) | 20-55 | 20-55 | 20-55 | 20-55 | 20-55 | 20-55 | 20-55 | 20-55 | 20-55 |

| Oil Capacity per Module | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Total Weight (kg) | 1400 | 2800 | 3150 | 3500 | 4200 | 4900 | 5600 | 6300 | 7000 |

| Excavator (T) | 20-30 | 20-30 | 20-30 | 20-40 | 20-40 | 20-40 | Hydraulic power unit | Hydraulic power unit | Hydraulic power unit |

Applications

- Pile head removal: Efficient removal of excess concrete from cast-in-place piles, prestressed pipe piles, and similar piles to ensure the pile top elevation meets design requirements.

- Excavation support removal: Used for breaking concrete support beams, retaining piles, and temporary support structures.

- Small structure demolition: Suitable for foundations, slabs, walls, piers, and other small reinforced concrete structures.

- Municipal engineering: Applicable to local road demolition, trench excavation, pipeline construction, and related tasks.

Features

- High efficiency and energy saving: Driven by a hydraulic system that delivers strong impact energy and high crushing efficiency—several times higher than manual methods—significantly shortening project timelines and reducing overall costs.

- Eco-friendly and low noise: Compared with blasting or pneumatic picks, the hydraulic pile breaker greatly reduces noise, dust, and vibration. This minimizes disturbance to surrounding structures and environments, making it ideal for urban construction sites with strict environmental requirements.

- Precise operation: Ensures accurate positioning and breaking while protecting reserved rebars, preventing accidental damage to design elements.

- Safe and reliable: Operators can remotely control the equipment and stay clear of the impact zone, effectively avoiding risks from flying debris or structural collapse and ensuring high construction safety.

- Compact structure: Lightweight, flexible, and easy to reposition, enabling rapid movement between pile locations and smooth operation in confined spaces.

- Flexible power matching: Typically powered by an excavator or loader through hydraulic quick couplings, maximizing the utilization of existing on-site equipment and improving investment efficiency.